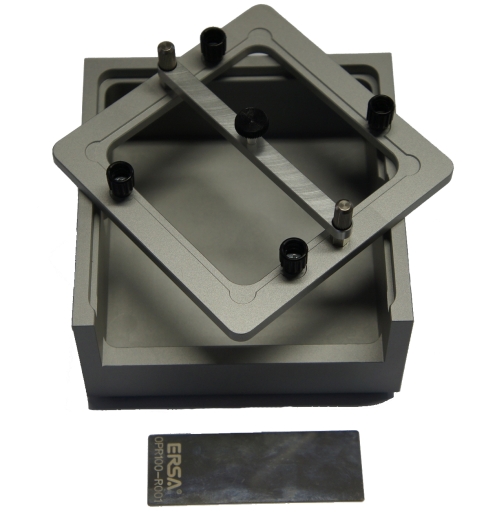

ERSA Dip & Print Station

The ERSA Dip & Print Station allows the user of ERSA rework systems to prepare components (application of solder paste or flux) in a simple, reliable and reproducible manner.

Optional dip stencils allow components to be dipped into flux or solder paste in a defined manner, thus creating a defined deposit on the solder connections

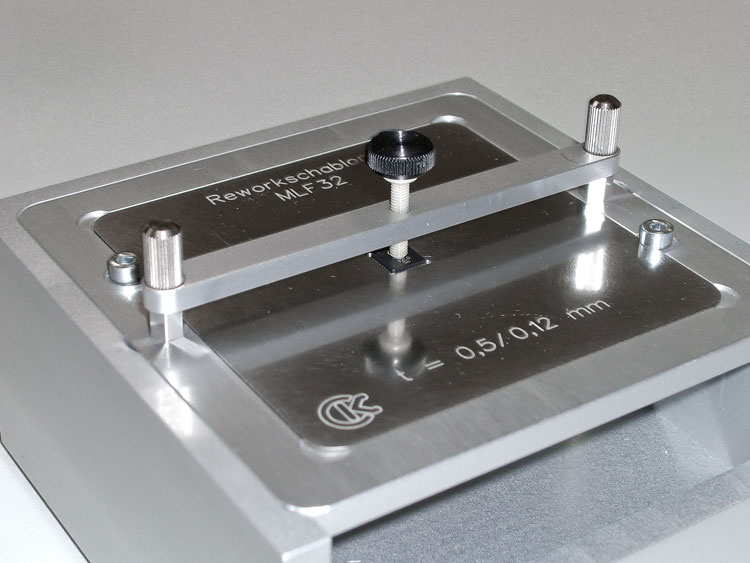

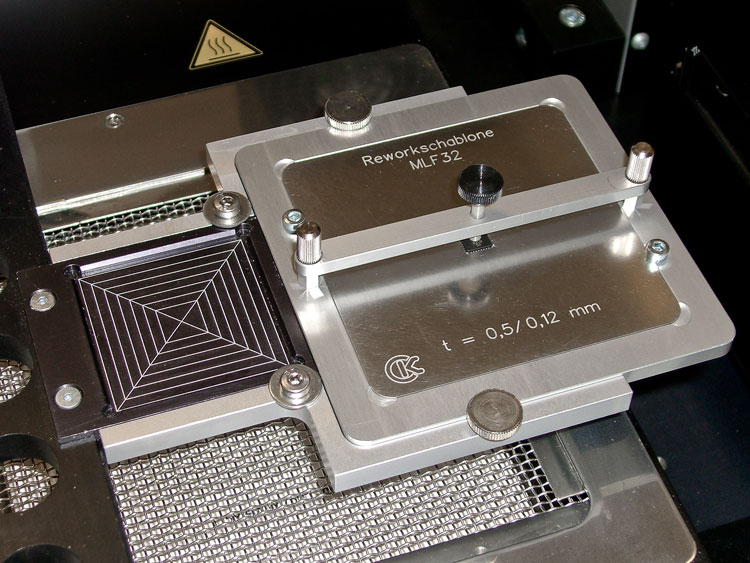

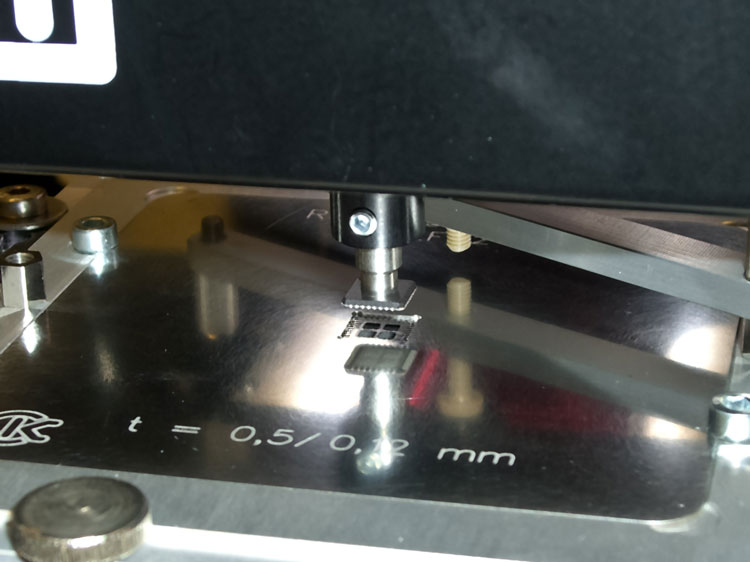

This method is suitable for BGAs and most fine-pitch components. With a component-specific print stencil, QFN / MLF connections and those of other SMD components, for example, can be easily and precisely provided with a solder paste deposit.

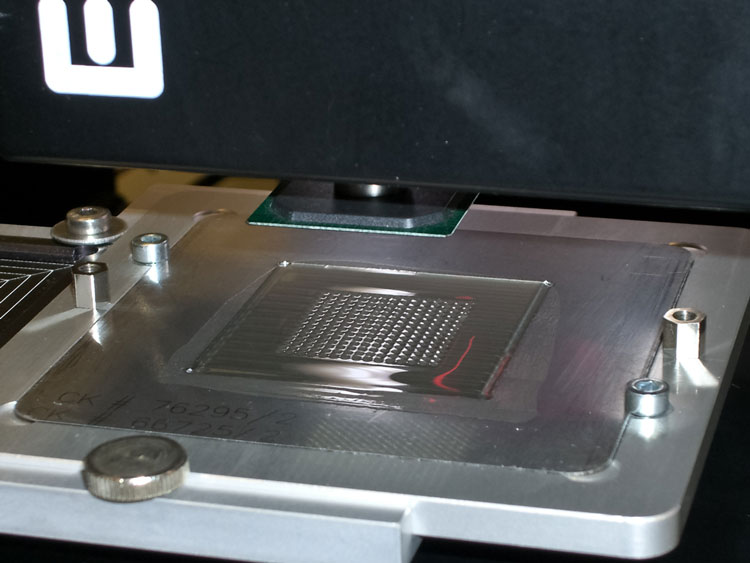

During the print process, the component clamped in the stencil is printed with solder paste from below, and then lifted out of the stencil by the placement unit and placed. A suitable frame fixture is available for every ERSA rework system to hold the stencil frame of the dip and print station on the placement system.